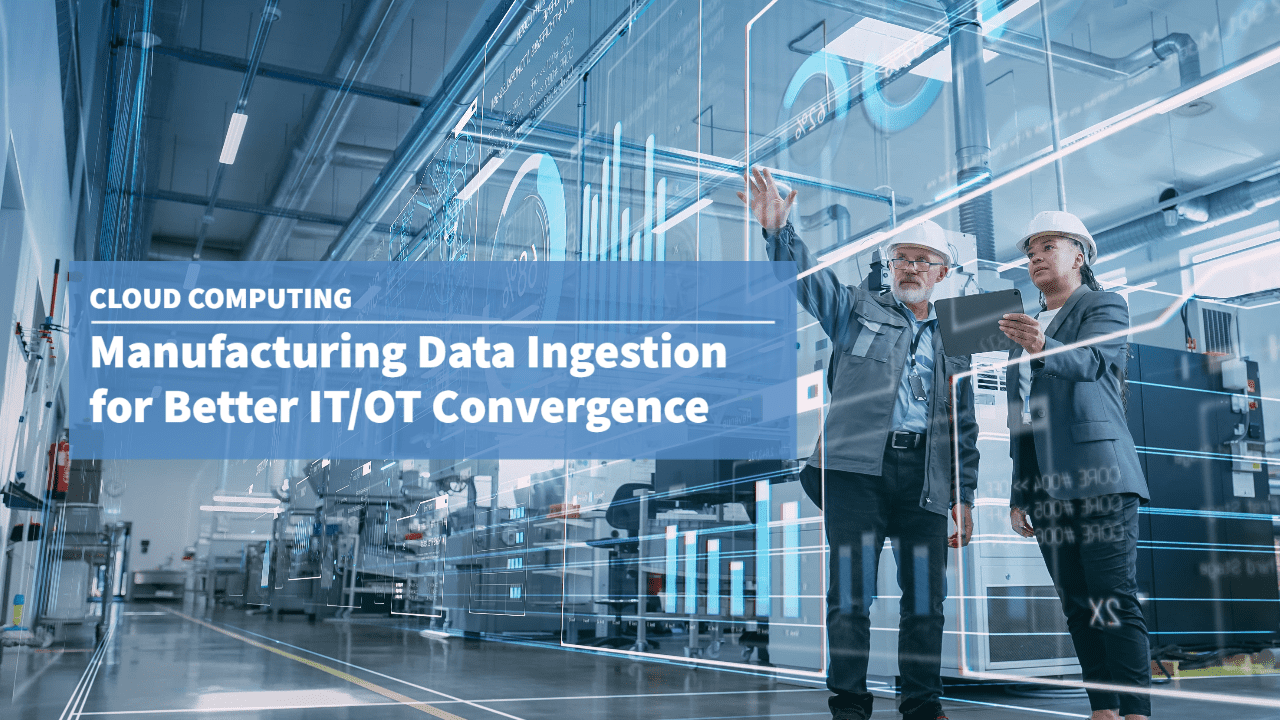

Industry 4.0 mandates the integration of advanced technologies such as IoT, AI, and machine learning (ML) into the production process, resulting in “smarter” factories that are more efficient, flexible, and responsive to customer demand. To achieve this synergy, there is a need to streamline the Manufacturing Data Ingestion from OT systems, and combine it with IT systems. Here is a reference architecture to achieve this integration.

More...

This article was originally published in Snowflake.

Use Case: Manufacturing Data Ingestion

Problem Statement

Industry 4.0 requires multiple categories of data, from time series and transactional data to structured and unstructured data, spread across disjoint IT and OT systems.

Realization Approach

A standardized reference architecture powered by Snoflake data platform that harnesses both IT and OT data with precise asset identification, plant hierarchy, and secure data sharing for customers and partners in order to accomplish IT/OT convergence.

Solution Space

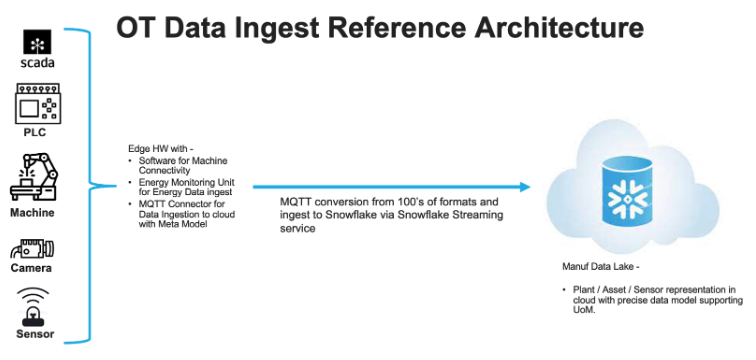

A highly scalable, fast and secure communication to ingest machine data, with support for edge analytics, and MQTT integration.

Accessing data from the manufacturing shop floor is one of the key topics of interest with the majority of cloud platform vendors due to the pace of Industry 4.0 adoption.

One of the key requirements of Industry 4.0 practices is the ability to collect and analyze vast amounts of data, allowing for improved efficiency, accuracy, and decision-making. For example, data can be used to optimize production processes, predict maintenance needs, and improve the quality of products. This is enabled by data and analytics platforms that provide speed, flexibility, and scale.

Building a New Model for Manufacturing Data Ingestion

Overall, the importance of data in Industry 4.0 cannot be overstated. A survey conducted by the IoT Business News states that companies that are not executing against an Industry 4.0 strategy are in the minority. A staggering 72% of the survey respondents report that they are in the process of implementing their Industry 4.0/Smart Factory with many initiatives in progress and some already completed. By leveraging I4.0 principals effectively, companies can drive operational efficiency, innovation, and competitiveness in the digital age.

Industry 4.0 requires multiple categories of data, from time series and transactional data to structured and unstructured data. It also relies on the integration of information technology (IT) and operational technology (OT) systems to support functions across the organization. Expanding on the key Industry 4.0 initiatives, such as improving efficiency and reducing downtime by including broader data sets (both internal and external), offers businesses even greater value and precision in the results.

OT teams must also deal with the added complexity of multiple communication protocols governing how data is exchanged in order to control and monitor manufacturing machines. This requires using specialized machine connector software for extracting data from these machines.

Both IT and OT data are important for Industry 4.0, and both data types must be understood holistically to derive meaningful insights to streamline production operations. Use cases like predictive quality require test (quality) data and machine process parameter data from sensors or PLCs, correlated together to build AI/ML models which can identify the combination of process parameters that may have led to the production of poor-quality products. Additionally, when working on sustainability use cases such as energy optimization in a manufacturing plant, we need additional specialized hardware and sensors to interface with power meters to extract relevant energy metrics.

Achieving Better Business Outcomes Through a Standardized Reference Architecture

Snowflake understands the importance of harnessing and ingesting both IT and OT data with precise asset identification, plant hierarchy, and secure data sharing for customers and partners in order to accomplish IT/OT convergence, and to help derive meaningful insights from your data. This is something that can be accomplished with Snowflake’s core platform capabilities along with our broad partner network, as well as by ingesting IT data from ERP, CRP, and SRM systems.

Given the complexity of ingesting OT systems data in near real time, Snowflake is establishing a standardized reference architecture. Working with our partners, this standardized reference architecture provides edge connectivity hardware supporting edge analytics, in addition to being a gateway device. Working with our partners, this architecture includes MQTT-based data ingestion into Snowflake. This provides a highly scalable, fast, flexible (OT data published by exception from edge to cloud), and secure communication to Snowflake. This publish action of OT data also preserves plant/asset data models with metadata, driving important business outcomes for manufacturers such as energy and asset performance optimization, predictive maintenance, and predictive quality—all enabled through the application of this integrated data architecture.

For our customers and partners, this changes the focus from building data ingestion and integration solutions to focusing instead on things that drive business outcomes.

This architecture establishes machine-to-cloud connectivity in a matter of days instead of weeks or months, providing companies with a faster realization of ROI. And for those customers who may have restrictions on analytics to be performed in cloud versus edge environments, the solution can scale from an edge gateway into an edge analytics platform.

The Snowflake Manufacturing capabilities rapidly bring together data from across functions, transactions, financial data, and now manufacturing-level detailed data, which is a critical enabler to help accelerate your Industry 4.0 initiatives. Stay tuned for more insights on Industry 4.0 and supply chain in the coming months.

Learn more about Snowflake for Manufacturing.