Many modern industrial facilities are turning to predictive maintenance strategies to increase uptime and reduce the cost of maintenance programs. Core to these strategies is condition monitoring, a maintenance approach that uses data collected from sensors to continuously monitor machine “health” and predict failures. This article covers a reference design for Modbus Vibration Monitoring using the the Golioth platform.

This post was originally published in Golioth.

Use Case: Modbus Vibration Monitoring

Problem Statement

Condition monitoring of industrial machines requires a continuous maintenance approach that relies on vibration data for early fault detection.

Realization Approach

An end-to-end device to cloud reference design ensures that the vibration data is continuously compared against the natural vibration signature of the equipment and premature failure conditions can be detected with the help of visualization.

Solution Space

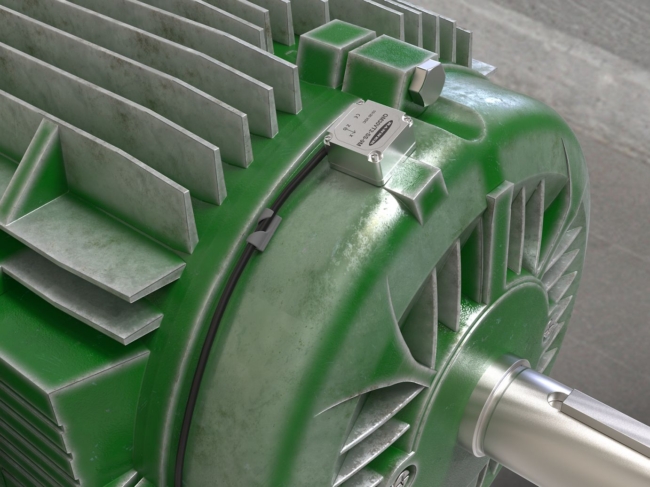

This approach is especially beneficial for predictive maintenance of rotating machines that frequently suffer from shaft misalignment, rotor balance issues, and bearing failures.

For rotating machinery like motors and turbines, the analysis of vibration data (vibration diagnostics) has proven to be the most effective method of condition monitoring and early fault detection. By continuously comparing the measured vibration signature against the “natural” vibration signature of the equipment, it’s possible to detect premature failure conditions due to shaft misalignment, rotor balance issues, bearing failures, etc.

Modbus Vibration Monitoring with Golioth

In this reference design, we demonstrate how to build a remotely-managed Industrial IoT vibration monitor designed for rotating machinery.

Firmware

The Modbus Vibration Monitoring firmware uses the Golioth Zephyr SDK to securely connect to the Golioth Cloud.

Periodically, the device reads temperature and vibration measurements from an off-the-shelf Banner QM30VT industrial vibration sensor using the Modbus protocol.

(Note that with Modbus, it’s possible to target a wide range of different industrial sensors. The Banner sensor is simply a starting point for this example.)

It then streams these vibration measurements directly to the Golioth Cloud over a cellular LTE connection, enabling the device to operate without connecting to internal facility networks.

The firmware source code for this reference design is available on GitHub at the following URL:

https://github.com/golioth/reference-design-modbus-vibration-monitor

Hardware

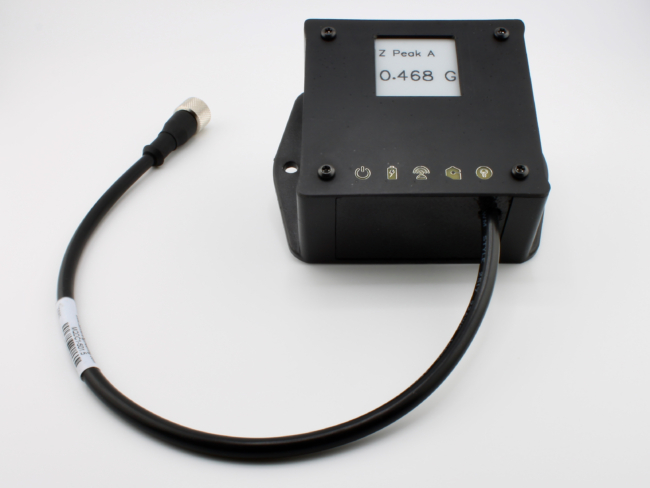

The vibration monitor hardware is built using the Golioth Aludel Mini prototyping platform. Additionally, it includes the Ostentus front panel featuring an ePaper display for sensor readings, back-lit LED indicators, and capacitive touch buttons.

Inside the box is the custom-designed Aludel carrier board. Specifically, the carrier board integrates a SparkFun nRF9160 Thing Plus cellular LTE module and a MikroE RS485 8 Click board.

The off-the-shelf Banner QM30VT Modbus vibration sensor connects to the Aludel platform via an industrial cabling system with M12 connectors. Although we’re using the QM30VT vibration sensor in this reference design, we can easily connect any other industrial RS-485 sensor to this design using the same M12 connector interface.

Cloud Management

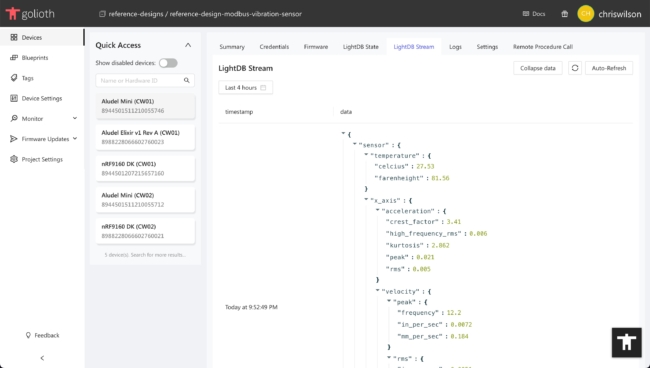

The Golioth Cloud provides all the services needed for deploying and remotely managing a fleet of condition monitoring devices:

- LightDB State: bidirectional real-time device state database

- LightDB Stream: database for storing time-series data

- Logging: centralized device log storage

- Settings: device settings management

- OTA: over-the-air firmware updates with one-click rollback

You can manage devices by logging into the Golioth web console, as well as using the REST API or the Command Line Tools.

Data Visualization of Modbus Vibration Monitoring

The Golioth REST API makes it easy for external applications or services to access the sensor data streamed from devices.

For example, we created a Grafana dashboard that displays the temperature & vibration measurements reported by each device:

Build It Yourself

What’s more, you can build your own Modbus Vibration Monitor using widely available off-the-shelf development boards from our partners!

We call this Follow-Along Hardware, and we think it’s one of the easiest ways to get started building an IoT proof-of-concept with Golioth.

Specifically, you will learn how to assemble the hardware, flash a pre-built firmware image onto the device, and connect to the Golioth cloud in minutes. The follow-along hardware runs the same open-source firmware as the custom Golioth hardware described above. We also provide instructions for building the firmware yourself if you want to make changes for your specific application.

We are releasing the nRF9160 DK Follow-Along Hardware Guide today, and plan to add support for additional development kits soon.

Project Page

For detailed information about the Modbus Vibration Monitor reference design, check out the project page at the following URL:

https://projects.golioth.io/reference-designs/modbus-vibration-monitor/

Additionally, you can drop us a note on our Forum if you have questions about this design.